TURNING HEADS

Heavy duty five axis boring mill boosts productivity, quality

Photos and story by Jim Barnes

June 2016 Reprinted with permission from Shop Metalworking Technology | www.shopmetaltech.com

THE PROBLEM

Need to machine more complex, high quality parts.

THE SOLUTION

A five axis boring mill with head changer.

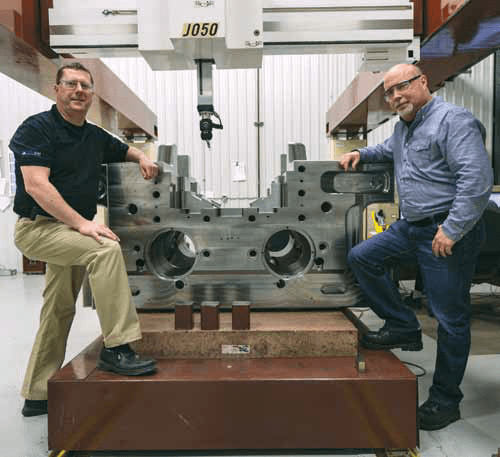

Standing by the newest Juaristi machine left to right: Larry Delaey, Mike Repuski and Dennis Alexander.

A close up look at the spindle head on the Juaristi machine.

A new machine is turning heads at AarKel Tool and Die Inc. of Wallaceburg, One of North America’s first five axis boring mills with a head changer is now in operation at the firm, which makes diecast and plastic injection tooling. The Juaristi TX3S was extensively customized for the company, management says. The company purchased the machine from Canadian machine tool distributor DiPaolo Machine Tools. AarKel Tool and Die Inc. began operations in Wallaceburg in 1977. Today, it is owned by Zynik Capital Corp., Vancouver, BC. Three facilities house some 10,220 sq m (158,000 sq ft) of operating space. Typically,170 employees work two shifts and a “weekend warrior” shift. In 2015, the firm did $48 million in sales. “We’re hoping to get to just over $50 million this year,” says Larry Delaey, president.

Diverse operation

Besides manufacturing diecast tooling (from 500 to 4,000 tons) and plastic injection tooling, the firm offers program management, prototype tool manufacturing, prototyping, part tryouts and full service, as well as full engineering and design capabilities. Delaey points out that the firm is different from most other tool shops. “We run both diecast tooling and plastic injection tooling. We’re probably one of the largest tool shops in North America that does both products.” With that kind of diversity, they work with a lot of different materials–notably H13 hardened, 4140, and P20. Equipment includes five axis CNC machines, high speed CNC machines, as well as sinker EDMs and five axis gun drills. The company also has internal welding capabilities. Among those machines are Juaristi boring mills. AarKel purchased its first in 1995, a second in 2005 and the new one in 2015, according to Dennis Alexander, operations manager. They have other brands of boring mills as well, so they have a good perspective on the technology available.

Machine operator Mike Repuski at the Heidenhain controls on the Juaristi machine.

Complex parts

The need to make more complex parts for customers both more efficiently and to top levels of quality drove the decision to acquire the new machine. Products are getting much more complex and demanding higher tolerances these days, says Delaey. “We have to be able to meet the quality and delivery demands of our customers.” AarKel went through an extensive evaluation process, comparing various machines that might meet their needs. Ultimately, they decided on Juaristi. However, that decision was just the start of the process. AarKel wanted some significant customization on its machine, to better adapt it to the shop. “We ended up changing the footprint of the machine. We wanted to keep the machine as compact as possible and yet still make it friendly for the operator,” says Alexander.

Customization

“With the lessons learned on our other two machines, we were able to move some things. We know how Juaristi works,” adds Alexander. Juaristi was an enthusiastic participant in the customization process. “We customized the axis travels to meet our customer work envelopes and moved panels along with the controller pendant to better meet the needs of our employees, based on our work to our customers.” says Alexander. “It went back and forth for quite some time,” he says. “But it is paying dividends right now.” The feature set that makes the machine a winner for AarKel includes:

- customization, supported by Juaristi.

- the five axis head and head changer

- 3.6 x 3.0 x 2.0 m. work envelope

- 40-tonne table

- robustness

“And the reliability and dependability of the machines, based on the ones we already have here,” says Delaey. The advance planning made the actual implementation straightforward. “We had to train our boring mill operators to use the five axis head,” says Alexander. “That was probably the biggest challenge.” “Juaristi has separated themselves from the rest with the five axes and the shuttle–that sets them apart,” says Alexander. “With the rotary table and the five axes, that gets you to the next level.”

“It eliminates a lot of the extra setups that we used to do,” says Delaey. “It enables us to do everything in one set up. No matter how complex the part is, we can do it and do it right the first time, every time.” SMT

Larry Delaey and Dennis Alexander say the Juaristi machine sets the company apart from competitors.

A corner lock of a holder block machined on the Juaristi five axis boring mill.

The Equipment

SMT discussed the machine with Robert Hart of DiPaolo Machine Tools, Mississauga,ON, the Canadian distributor for Juaristi. The key features he identifies are:

- 30 m/min. rapid feed with a linear guideway

- spindle motor power of 37 kW

- spindle capable of up to 3,500 rpm

- 130-mm spindle quill diameter

- 60-tool carousel

“One of the things that separates Juaristi from the other manufacturers of this style of machine is the head changer,” says Hart. “Also, the Y-axis is symmetrical, so the spindle is centrally located in the Y axis column.” On many conventional boring mills, the spindle is set off to one side. The Juaristi configuration offers advantages in rigidity, he says. “It’s a fast machine for its size,” he adds. “The table is on linear guides. The rotary axis is hydrostatic, which gives it superior damping capabilities.” Ultimately, the machine combines the capabilities of a boring mill and a semi-finish machine in one package, says Hart.